Description

Product Highlights

● Light panel weight

● Available in 600x600x28mm and 600x600x30mm

● High-Density chipboard with 720kg/m3

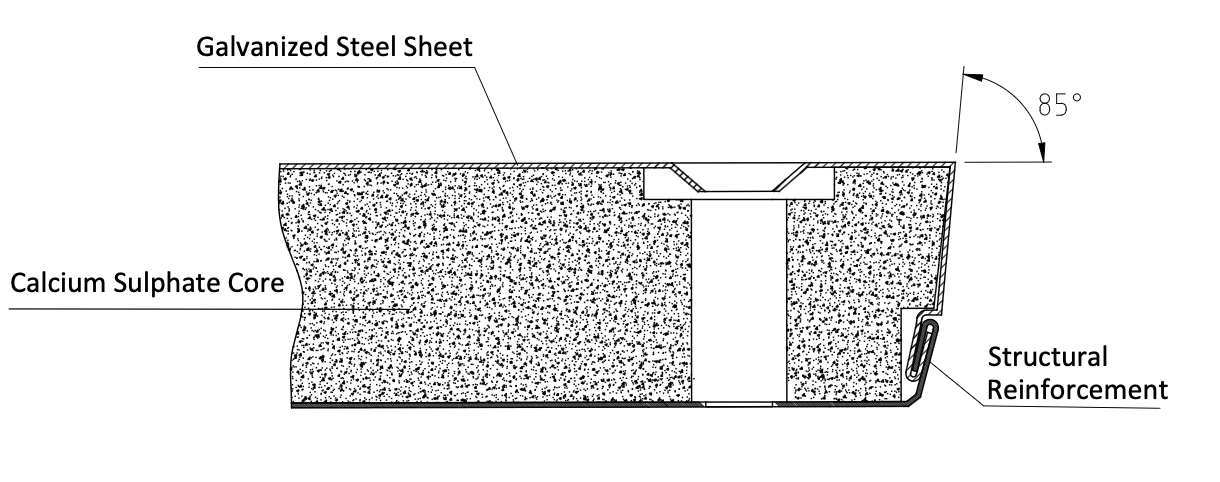

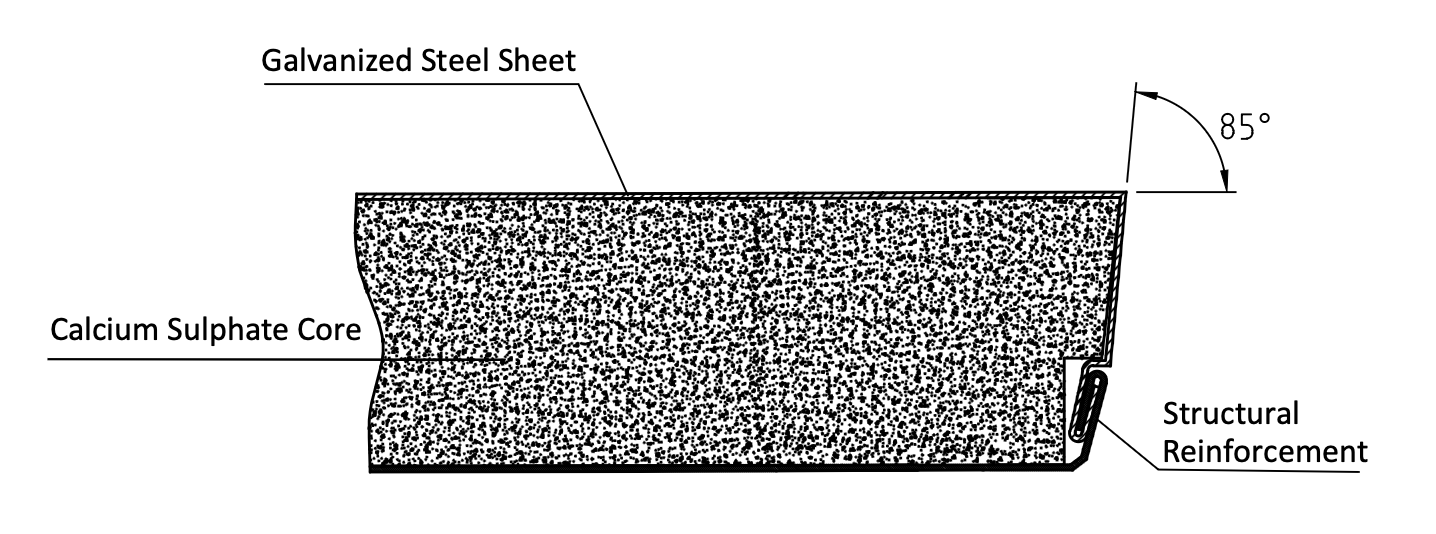

● GI Steel Sheet available in 0.3/0.4/0.5mm

● Structural Reinforcement to achieve better loading capacity

● Available for Corner Lock Installation

● Available for Gravity Lay Installation

● Available in 600x600x28mm and 600x600x30mm

● High-Density chipboard with 720kg/m3

● GI Steel Sheet available in 0.3/0.4/0.5mm

● Structural Reinforcement to achieve better loading capacity

● Available for Corner Lock Installation

● Available for Gravity Lay Installation

SYSTEM PERFORMANCE CRITERIA

System performance criteria are the most important to consider because they represent the performance in a typical installation. Panel only criteria such as concentrated load is often used to specify floor systems however, the test is not representative of an actual installation because it is performed with the panel testing blocks, not actual understructure.

| System Performance Criteria | |||||||

| System Type | Static Loads | Rolling Loads | |||||

| Panel | Panel Size | Concentrated Load |

Safety Factor (min.2.0) |

Ultimated load | Uniform Load | 10 Passes | 10,000 Passes |

| EWC800 | 600x600x28mm | 368kg/800lbs | Pass | 736kg/1600lbs | 1650kg/m2 | 318kg 700lbs |

275kg 600lbs |

| EWC1000 | 600x600x30mm | 454kg/1000lbs | Pass | 909kg/2000lbs | 2300kg/m2 | 368kg 800lbs |

318kg 700lbs |

*A tests are performed using CISCA’s Recommend Test Procedures for Access Floors with the exception of Design Load

1. Design load is tested using CISCA Concentrated Load test method on actual understructure instead of steel blocks. Design load is determined by taking the lesser value of ultimate load divided by two or the point at which permanent damage begins to occur (yield point).

2. Safety factor is the multiple of Design load to the Ultimate Load. International standards and Dawn Modular Floor recommend’ a minium of 2.

2. Safety factor is the multiple of Design load to the Ultimate Load. International standards and Dawn Modular Floor recommend’ a minium of 2.

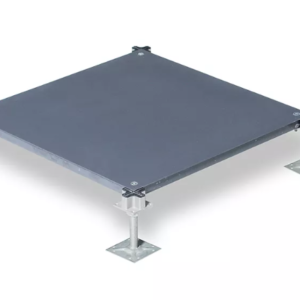

INSTALLATION

The finished access floor wil be rigid, free from vibration and rocking panels within a 3mm level over the entire space. Panels will be accurately cut to fit around all permanent features. All whole panels will be completely interchangeable allowing for any future changes. The access foor will maintain these origina conditions when sufficient panels have been removed for normal underfloor access.

ADVANTAGES

● Durability and Stability: The encapsulation of the wood core with protective materials such as galvanized steel or aluminum enhances the floor’s durability and stability. This makes the flooring capable of supporting heavy equipment and high foot traffic.

● Resistance to Wear and Tear: The protective encapsulation provides a high degree of resistance to wear, tear, and impacts, ensuring the longevity of the flooring system.

● Moisture Resistance: The encapsulating material prevents moisture from penetrating the wood core, protecting the floor from potential damage due to moisture or spills.

● Easy Access to Utilities: The raised design of the flooring provides a convenient underfloor space for housing utilities such as electrical wiring, data cables, and HVAC systems. This makes maintenance, upgrades, and changes to these systems easier.

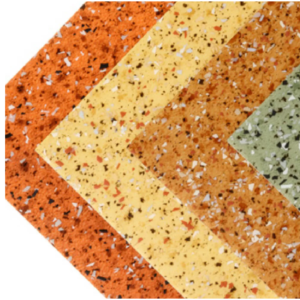

● Aesthetic Appeal: Encapsulated woodcore raised access floors can be finished with a variety of coverings to match the aesthetic of the space, offering both functionality and visual appeal.

● Sound Damping: The composition of these floors can help to dampen sound, contributing to a quieter environment.

● Flexibility: Despite their durability and strength, these floors offer flexibility. The modular nature of the panels allows for reconfiguration as needed, making the floor system adaptable to changing needs.

● Resistance to Wear and Tear: The protective encapsulation provides a high degree of resistance to wear, tear, and impacts, ensuring the longevity of the flooring system.

● Moisture Resistance: The encapsulating material prevents moisture from penetrating the wood core, protecting the floor from potential damage due to moisture or spills.

● Easy Access to Utilities: The raised design of the flooring provides a convenient underfloor space for housing utilities such as electrical wiring, data cables, and HVAC systems. This makes maintenance, upgrades, and changes to these systems easier.

● Aesthetic Appeal: Encapsulated woodcore raised access floors can be finished with a variety of coverings to match the aesthetic of the space, offering both functionality and visual appeal.

● Sound Damping: The composition of these floors can help to dampen sound, contributing to a quieter environment.

● Flexibility: Despite their durability and strength, these floors offer flexibility. The modular nature of the panels allows for reconfiguration as needed, making the floor system adaptable to changing needs.

Reviews

There are no reviews yet.