Description

SYSTEM PERFORMANCE CRITERIA

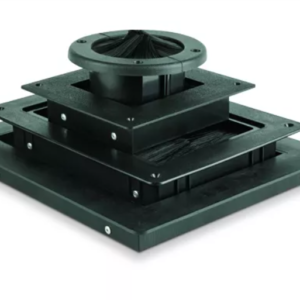

System performance criteria are the most important to consider because they represent the performance in a typical installation. Panel only criteria such as concentrated load is often used to specify floor systems however, the test is not representative of an actual installation because it is performed with the panel testing blocks, not actual understructure.

| Project Detail | Finish | System Resistance | Material | Concentrated Load | Ultimated Load | Uniform Load | Special Treatment |

| HLS300 | HPL/PVC | Conductive 1O4-1O6Ω or Static Dissipative 1O6-1O9Ω | Die-cast aluminum | 300kgf/6.45cm2 Deflection<=2.0mm |

600kgf/6.45cm2 | 600kgf/m2 Deflection<=1.0mm |

Epoxy coating or Ni-Cr plating |

| HLS500 | HPL/PVC | Conductive 1O4-1O6Ω or Static Dissipative 1O6-1O9Ω | Die-cast aluminum | 500kgf/6.45cm2 Deflection<=2.0mm | 1000kgf/6.45cm2 | 1000kgf/m2 Deflection<=1.0mm |

Epoxy coating or Ni-Cr plating |

| HLS700 | HPL/PVC | Conductive 1O4-1O6Ω or Static Dissipative 1O6-1O9Ω | Die-cast aluminum | 700kgf/6.45cm2 Deflection<=2.0mm | 1400kgf/6.45cm2 | 1400kgf/m2 Deflection<=1.0mm |

Epoxy coating or Ni-Cr plating |

| HLS1000 | HPL/PVC | Conductive 1O4-1O6Ω or Static Dissipative 1O6-1O9Ω | Die-cast aluminum | 1000kgf/6.45cm2 Deflection<=2.0mm | 2000kgf/6.45cm2 | 2000kgf/m2 Deflection<=1.0mm |

Epoxy coating or Ni-Cr plating |

| HLS1200 | HPL/PVC | Conductive 1O4-1O6Ω or Static Dissipative 1O6-1O9Ω | Die-cast aluminum | 1200kgf/6.45cm2 Deflection<=2.0mm | 2400kgf/6.45cm2 | 2200kgf/m2 Deflection<=1.0mm |

Epoxy coating or Ni-Cr plating |

| HLS1500 | HPL/PVC | Conductive 1O4-1O6Ω or Static Dissipative 1O6-1O9Ω | Die-cast aluminum | 1500kgf/6.45cm2 Deflection<=2.0mm | 3000kgf/6.45cm2 | 3000kgf/m2 Deflection<=1.0mm |

Epoxy coating or Ni-Cr plating |

| HLS2000 | HPL/PVC | Conductive 1O4-1O6Ω or Static Dissipative 1O6-1O9Ω | Die-cast aluminum | 2000kgf/6.45cm2 Deflection<=2.0mm | 4000kgf/6.45cm2 | 4000kgf/m2 Deflection<=1.0mm |

Epoxy coating or Ni-Cr plating |

| HLS2500 | HPL/PVC | Conductive 1O4-1O6Ω or Static Dissipative 1O6-1O9Ω | Die-cast aluminum | 2500kgf/6.45cm2 Deflection<=2.0mm | 5000kgf/6.45cm2 | 5000kgf/m2 Deflection<=1.0mm |

Epoxy coating or Ni-Cr plating |

| HLS3000 | HPL/PVC | Conductive 1O4-1O6Ω or Static Dissipative 1O6-1O9Ω | Die-cast aluminum | 3000kgf/6.45cm2 Deflection<=2.0mm | 6000kgf/6.45cm2 | 6000kgf/m2 Deflection<=1.0mm |

Epoxy coating or Ni-Cr plating |

*A tests are performed using CISCA’s Recommend Test Procedures for Access Floors with the exception of Design Load

1. Design load is tested using CISCA Concentrated Load test method on actual understructure instead of steel blocks. Design load is determined by taking the lesser value of ultimate load divided by two or the point at which permanent damage begins to occur (yield point).

2. Safety factor is the multiple of Design load to the Ultimate Load. International standards and Dawn Modular Floor recommend’ a minium of 2.

2. Safety factor is the multiple of Design load to the Ultimate Load. International standards and Dawn Modular Floor recommend’ a minium of 2.

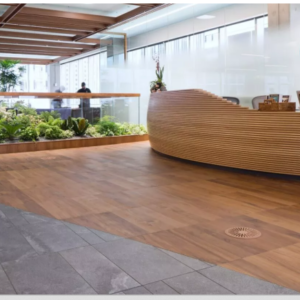

INSTALLATION

The finished access floor wil be rigid, free from vibration and rocking panels within a 3mm level over the entire space. Panels will be accurately cut to fit around all permanent features. All whole panels will be completely interchangeable allowing for any future changes. The access foor will maintain these origina conditions when sufficient panels have been removed for normal underfloor access.

ADVANTAGES

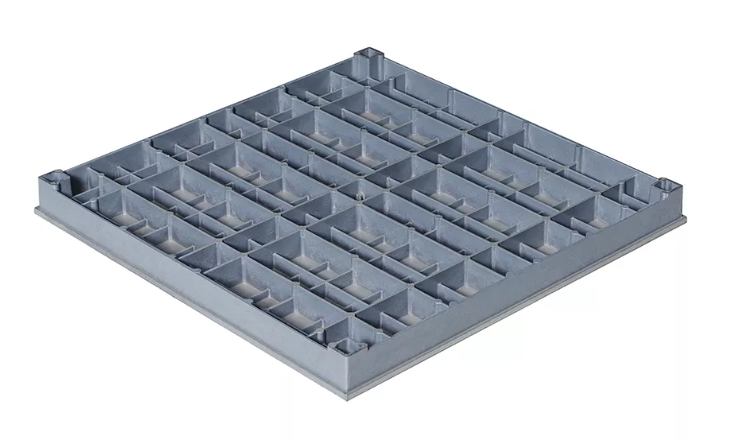

● Contamination Control: The seamless, non-porous surface of these floors helps reduce the accumulation of particulate matter, a crucial factor for cleanrooms where strict contamination control is required.

● High Load Capacity: Aluminum die-cast solid raised floors are designed to handle high loads. They can support the weight of heavy equipment commonly used in cleanrooms, data centers, and other similar environments.

● Precision and Uniformity:The die-casting process ensures high precision and uniformity, resulting in a stable, seamless surface that minimizes dust traps and facilitates cleaning.

● Easy Access to Utilities: The raised design allows easy access to utilities such as electrical wiring, data cables, and HVAC systems, facilitating maintenance and changes without disrupting the cleanroom operations.

● Durability and Load Capacity: Aluminum die-cast panels are robust and durable, capable of supporting heavy equipment often found in cleanrooms.

● High Load Capacity: Aluminum die-cast solid raised floors are designed to handle high loads. They can support the weight of heavy equipment commonly used in cleanrooms, data centers, and other similar environments.

● Precision and Uniformity:The die-casting process ensures high precision and uniformity, resulting in a stable, seamless surface that minimizes dust traps and facilitates cleaning.

● Easy Access to Utilities: The raised design allows easy access to utilities such as electrical wiring, data cables, and HVAC systems, facilitating maintenance and changes without disrupting the cleanroom operations.

● Durability and Load Capacity: Aluminum die-cast panels are robust and durable, capable of supporting heavy equipment often found in cleanrooms.

● Corrosion Resistance: Aluminum is naturally corrosion-resistant, ensuring the longevity of the flooring system even in environments with a variety of chemicals.

● Sustainability: Aluminum is recyclable, making these flooring systems a more environmentally friendly choice.

● Thermal Conductivity: Aluminum’s good thermal conductivity helps in heat dissipation, a valuable attribute in environments with heat-generating equipment.

● Sustainability: Aluminum is recyclable, making these flooring systems a more environmentally friendly choice.

● Thermal Conductivity: Aluminum’s good thermal conductivity helps in heat dissipation, a valuable attribute in environments with heat-generating equipment.

Reviews

There are no reviews yet.